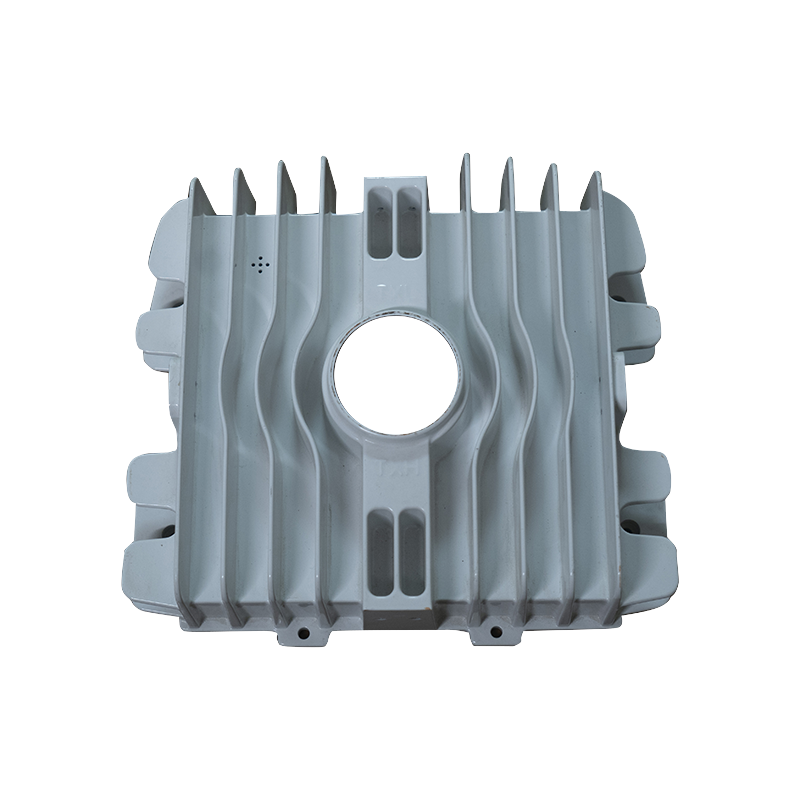

Lefapheng la mechini ea indasteri le boenjiniere ba likoloi, bohlokoa ba likarolo tse tšoarellang tse netefatsang ts'ebetso e ntle bo ke ke ba feteletsoa. Har'a likarolo tsena,likoahelo tsa ho lahla alloy ea aluminiumli hlahile e le tharollo ea bohlokoa le e feto-fetohang. Ka matla a tsona a ikhethang, tlhaho e bobebe, le thepa e sa senyeheng ke mafome, likoahelo tsena li bapala karolo ea bohlokoa ho sireletseng mechini ea bohlokoa le ho ntlafatsa ts'ebetso ea tsona ka kakaretso. Sengoliloeng sena sa blog se hlahloba bohlokoa ba likoahelo tsa ho betla tsa alloy ea aluminium, se totobatsa likarolo tsa tsona tsa bohlokoa, melemo le lits'ebetso.

1. Tšireletso e Matla:

Likoahelo tsa ho betla tsa alloy ea aluminium li etselitsoe ka ho khetheha ho sireletsa le ho sireletsa likarolo tsa bohlokoa linthong tse fapaneng tsa kantle, ho kenyeletsoa lerōle, lithōle, mongobo le maemo a leholimo a thata. Ka ho sebetsa e le tšitiso e sireletsang, likoahelo tsena li thibela lintho tse sa batleheng ho kena le ho senya mechine, e leng se fokotsang kotsi ea ho se sebetse hantle kapa ho senyeha. Ho mamella ha tsona le ho hanyetsa tšusumetso ho tiisa hore likarolo tse koahetsoeng li tla phela nako e telele.

2. E bobebe ebile e tenyetseha:

Ha ho bapisoa le thepa e 'ngoe e kang tšepe kapa tšepe, li-alloy tsa aluminium li bontša thepa e ikhethang e bobebe, e leng se etsang hore li be ntle bakeng sa likoahelo tsa ho betla. Boima bo fokotsehileng bo molemo mabapi le lipalangoang, ts'ebetso le boiketlo ba ho kenya ka kakaretso. Tlhaho ena e bobebe e nolofalletsa ho tenyetseha ho eketsehileng ha ho ntse ho raloa likarolo tse rarahaneng, ho netefatsa hore li lekana hantle le ts'ebetso e ntlafetseng. Ho feta moo, li-alloy tsa aluminium li ka etsoa ka libopeho tse fapaneng, e leng se lumellang ho fetoloa ha likoahelo tsa ho betla ho latela litlhoko tse itseng tsa lisebelisoa.

3. Ho tsamaisa mocheso:

Tšobotsi e 'ngoe e ntle ea likoahelo tsa ho betla ka alloy ea aluminium ke ho tsamaisa ha tsona mocheso hantle. Li-alloy tsa aluminium li na le bokhoni bo phahameng ba ho qhala mocheso, bo thusang ho laola mocheso o hlahisoang ke mechini e koetsoeng ka katleho. Boleng bona bo bohlokoa haholo bakeng sa lits'ebetso moo taolo ea mocheso e leng ea bohlokoa ho boloka ts'ebetso e ntle kapa ho thibela ho chesa haholo. Ka ho qhala mocheso ka katleho, likoahelo tsa ho betla ka alloy ea aluminium li thusa ho atolosa nako ea bophelo ea lisebelisoa tse bonolo le ho ntlafatsa katleho ea tsona ka kakaretso.

4. Khanyetso ea ho Sila:

Ntle le ho tšoarella ha tsona, litšepe tse kopantsoeng tsa aluminium li tsebahala ka ho hanyetsa mafome ka tsela e ikhethang. Thepa ena e etsa hore li tšoanelehe haholo bakeng sa likoahelo tsa ho betsa tse pepesehetseng likarolo tse fapaneng tsa tikoloho, tse kang mongobo, lik'hemik'hale kapa metsi a letsoai. Ho hanyetsa mafome ha ho netefatse feela tšireletso ea mechini empa hape ho fokotsa litšenyehelo tsa tlhokomelo tse amanang le ho lokisa kapa ho nkela tse ling sebaka ka lebaka la tšenyo ea mafome.

5. Mefuta e mengata ea Likopo:

Likoahelo tsa ho lahla alloy ea aluminiumfumana lits'ebetso tse pharaletseng liindastering tse fapaneng. Li sebelisoa hangata tlhahisong ea likoloi bakeng sa likoahelo tsa enjene, li-gearbox le likoahelo tsa phetisetso. Indastering ea lifofane, li sebetsa e le matlo a tšireletso bakeng sa likarolo tsa bohlokoa tsa elektroniki kapa litsamaiso tsa hydraulic. Ho feta moo, li sebelisoa haholo tlhahisong ea mechini e boima, lisebelisoa tsa tlhahiso ea motlakase, esita le lisebelisoa tsa elektroniki tsa bareki, ka lebaka la tlhaho ea tsona e feto-fetohang le melemo eo li fanang ka eona.

Likoahelo tsa ho betla ka alloy ea aluminium li fetohile karolo ea bohlokoa ea mechini ea sejoale-joale ka lebaka la litšobotsi tsa tsona tse sa bapisoeng tsa ho tšoarella, moralo o bobebe, ho tsamaisa mocheso le ho hanyetsa mafome. Likoahelo tsena ha li sireletse likarolo tsa bohlokoa feela empa li boetse li ntlafatsa ts'ebetso le ho netefatsa nako e telele ea lisebelisoa. Ha theknoloji e ntse e tsoela pele, tlhoko ea likoahelo tsa ho betla ka alloy ea aluminium e lebelletsoe ho hola, e sebeletsa liindasteri tse fapaneng tse itšetlehileng ka mechini e matla le e sebetsang hantle.

Nako ea poso: Pulungoana-20-2023