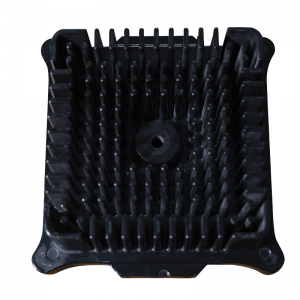

Die-cast tloaelo heatsink bakeng sa Radiator

Mokhoa oa ho futhumatsa mocheso

Moqapi oa lisebelisoa

Khatello e phahameng ea lefu la ho lahla

Ho fokotsa

Deburring

Ho qhomisa lehlabathe

Ho bentša bokaholimo

Ho roala ka phofo

CNC ho tlanya le ho sebetsa

Helical kenya

Phekolo ea Bokaholimo

1. K'hemik'hale oxidation

2. Ho taka

3. Electrophoresis

4. Anodizing

5. Ho roala ka phofo

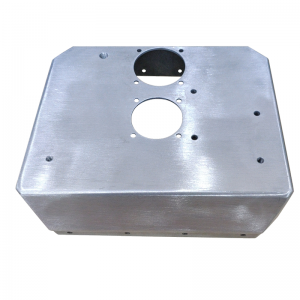

Die cast heat sinks

Lisinki tsa mocheso oa Die cast li nepahetse haeba u hloka sinki ea mocheso e entsoeng ka aluminium e etselitsoeng tloaelo.Li etsoa ka ho qobella aluminium ea metsi tlas'a khatello e phahameng ka har'a liforomo tsa tšepe .Die casting heat sink e tumme 'marakeng hobane e entsoe ka motsoako oa aluminium.Ena ke thepa e ratoang bakeng sa sink ea mocheso oa die casting.Ts'ebetso tsena tsa ho lahlela lefu li loketse ho fihlela tlhoko e 'ngoe le e' ngoe ea projeke le ho etsoa tlhahiso e potlakileng.

Nako ea ho etella pele e potlakileng ke matsatsi a 35-40 feela

Ts'ebetso e phahameng holim'a li-anodized surface finishes

Litekanyo tse phahameng tse thata li laoloa ka hare ho +/-0.05mm

Baenjiniere ba thusa ho phethela ho tloha ho moralo ho isa ho tlhahiso

Melemo ea Die Cast Heat Sinks

Ha ho bapisoa le mekhoa e meng ea tlhahiso, die casting e fana ka melemo e latelang:

1. Hlahisa libopeho tse rarahaneng tsa 3D tse ke keng tsa khoneha ka extrusion kapa forging

sink ea mocheso ea aluminium, foreime, matlo, sebaka se koaletsoeng le lintho tse tiisang li ka kopanngoa ka ho lahla ha 'ngoe.

2.Holes ka kored in die casting

3.Sekhahla se phahameng sa tlhahiso le theko e tlaase

4.Tight tolerances

5.Dimensionally stable

6. Mechine ea bobeli ha e hlokehe

Fana ka libaka tse bataletseng tse ikhethang (tse loketseng ho kopana pakeng tsa siling ea mocheso le mohloli)

Litekanyetso tsa ho hanyetsa kutu ho tloha ho tse ntle ho ea holimo

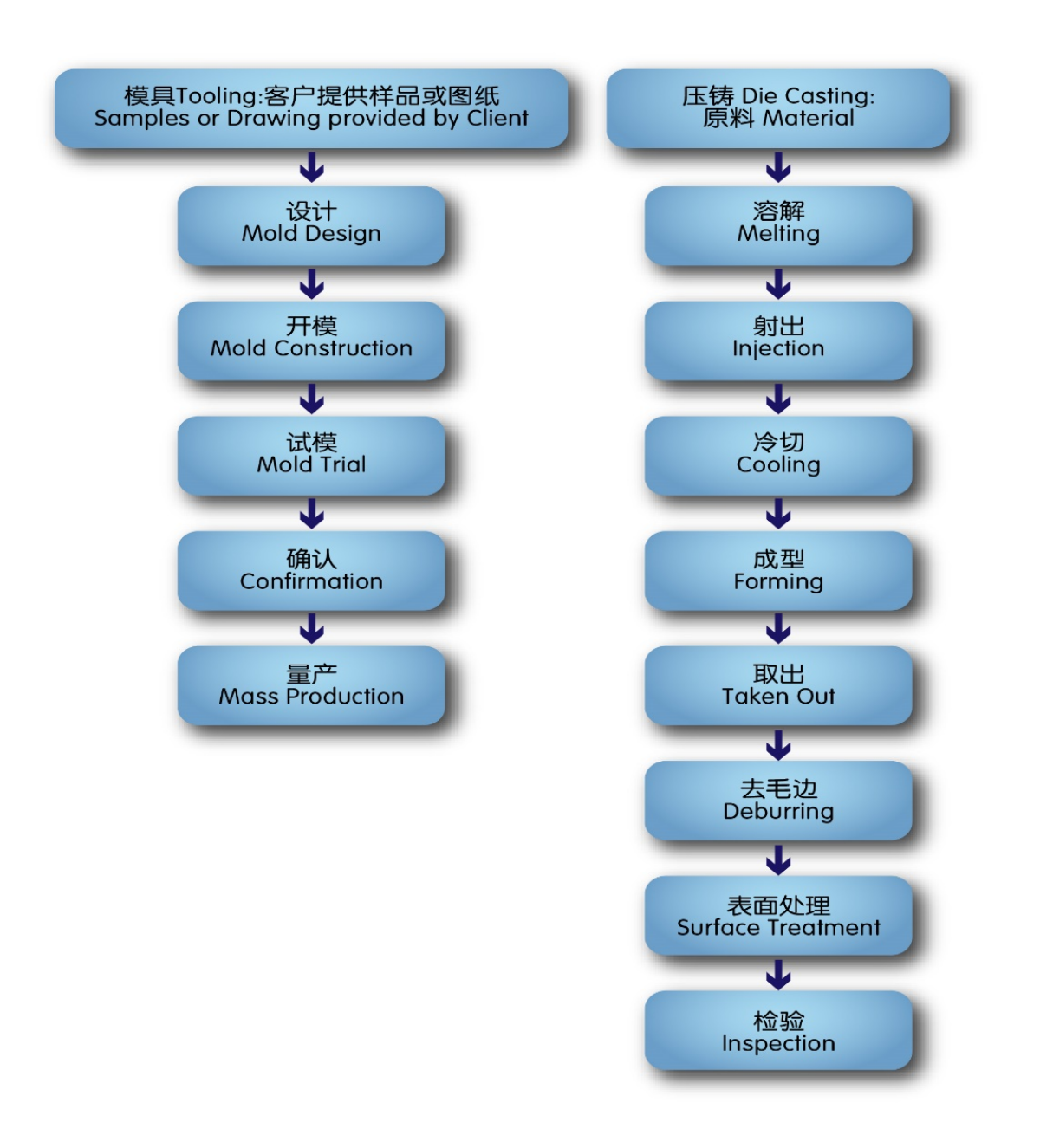

Kingrun process flow

Ha ho bapisoa le mekhoa e meng ea tlhahiso, die casting e fana ka melemo e latelang:

1. Hlahisa libopeho tse rarahaneng tsa 3D tse ke keng tsa khoneha ka extrusion kapa forging

Sekepe sa mocheso, foreimi, matlo, sekoahelo le lintho tse tiisang li ka kopanngoa ka ho lahla ha 'ngoe

2.Holes ka kored in die casting

3.Sekhahla se phahameng sa tlhahiso le theko e tlaase

4.Tight tolerances

5.Dimensionally stable

6. Mechine ea bobeli ha e hlokehe

Fana ka libaka tse bataletseng tse ikhethang (tse loketseng ho kopana pakeng tsa siling ea mocheso le mohloli)

Litekanyetso tsa ho hanyetsa kutu ho tloha ho tse ntle ho ea holimo

EMI e ntle haholo e sireletsang RFI